Spartan |

Spartan Ⅱ Basic |

Spartan Ⅱ Deluxe |

Spartan 3 PLC |

Spartan 3 PLC with PAC |

Spartan 3 PLC with PAC & RFID |

|

|---|---|---|---|---|---|---|

| Feature | Entry Level Designed specifically for injection | Designed for RTM lite | Designed for automated RTM Lite | Designed for automated RTM Lite with touch screen programmable | Designed for high volume automated RTM Lite | Designed to simplify high volume production when numerous mold sizes are utilized |

| Complete recirculation | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Pneumatic trigger | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Air/Solvent Flush | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Low pressure injection | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Spartan dispense head | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Positive feed SSP catalyst slave pump | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Stroke Counter | ◯ | ◯ | ◯ | ◯ | ◯ | |

| Auto-Valve ready | ◯ | ◯ | ◯ | ◯ | ◯ | |

| Low pressure injection with Accu-Pressure | ◯ | ◯ | ◯ | ◯ | ◯ | |

| User Friendly Control panel | ◯ | ◯ | ◯ | ◯ | ||

| Dispense timer | ◯ | ◯ | ◯ | ◯ | ||

| Adjustable independent solvent flush | ◯ | ◯ | ◯ | ◯ | ||

| Independent air flush toggle switch | ◯ | ◯ | ◯ | ◯ | ||

| Adjustable Gel-Timer | ◯ | ◯ | ◯ | ◯ | ||

| Touch Screen Programmable | ◯ | ◯ | ◯ | |||

| 30 Programmable injection settings | ◯ | ◯ | ◯ | |||

| Programmble digital Gel-Timer | ◯ | ◯ | ◯ | |||

| Programmble digital aer / solvent flush | ◯ | ◯ | ◯ | |||

| Programmble Automatic Catalyst | ◯ | ◯ | ||||

| Programmble radio frequency identification tags | ◯ | |||||

| Unlimited proframming | ◯ | |||||

| Password Protected | ◯ | |||||

| Exteded Hose Lengths | Optional | Optional | Optional | Optional | Optional | Optional |

| Inline heater | Optional | Optional | Optional | Optional | Optional | Optional |

| Cart, Mast and Boom mounted | Optional | Optional | Optional | Optional | Optional | Optional |

A Full line of solutions for resin transfer molding

Resin transfer molding (RTM) is a closed mold manufacturing process. Finished parts are made by introducing polyester or vinyl ester resins into closed molds containing fiberglass, carbon or other reinforcements.

Whether your process is traditional RTM, Light RTM, Vacuum Infusion Process (VIP), Closed Carvity Bag Molding (CCBM), or other similar process, GlasCraft offers a complete line of RTM systems to fit your application.

GlasCraft RTM Systems procide control at low pressure - the key to successful Light RTM injection

Typical applications:

Advanced features for automated, high-volume TRM preduction

Advanced GlasCraft models are available with the following:

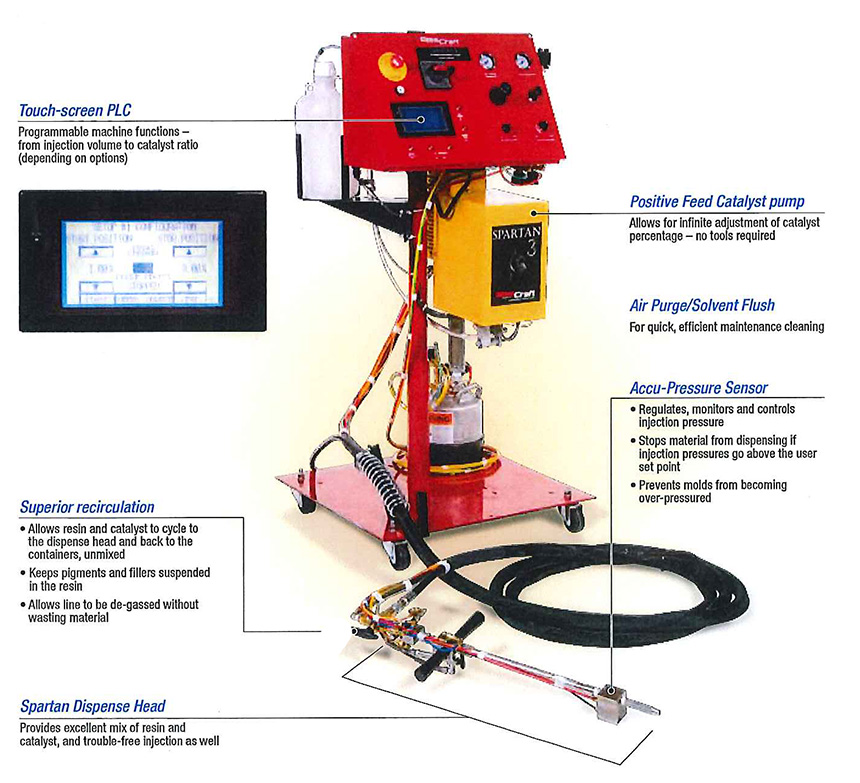

Touch screen PLC

Programmable logic controller allows you to program injection vollume and catalyst ratio settings. Reduces operator error. Results in less wasted material and improved productivity.

Programmable digital ari / solvent flush

Flushes out the stantic mixer with a pre-programmed amount of solvent. Can bi used in combination with the air purge function for extra cleaning power.

Programmable Automathic Catalyst (PAC)

ldeal for manufactures of larger parts. PAC allows you to program and adjust catalyst ratios for the injection cycle. By reducing the catalyst during the last part of the infusion sysle, the part cures at a more even rate.

Programmable Radio Frequency Identification tags (RFID)

Each mold your plant gets a unique RFID tag that you program with specific parameters such as amount of resin required and a catalyst infection profile. The operator simply sxans the tag and the machine automatically loads the pre-programmed settings. RFID tags eliminate operator error and programming errors, and save wasted material as well.

In addition, RFID tags provide your facility with unlimited programming potential. That's because the system only stores the current RFID tag's dispense parameters. Since all molding parameters are stored on each chip, you can have an unlimited number of RFID-tagged molds in your production facility.

Password Protected PLC

Spartan 3 PLC with PAC and RFID systems are designed with password protection so thea operators cannot change mold settings and parameters.

Advantages of RTM

A growing number of companies are moving to closed mold processes cecause it offers many significnant benefits: